Alcohol

Distilleries face problems of ullage and evaporation. Vapor recovery can solve both.

Our Services

We want to help you make more money while saving the environment.

Contact us to find out just how much you can save and quantify your environmental impact.

Overview

Alcohol per liter is far more expensive than most chemicals or fuels. The ethanol can easily be recovered so there is no need to top off distilled alcohol to maintain concentration, saving you money. Unlike other applications, alcohol is ingested by customers and as a result the manufacturing of our machines requires using FDA approved food grade materials for recovery.

Distilleries that sell billions can make millions. When we recover alcohol it includes not only the ethanol but also the congeners. Trust only the best vapor recovery else the output could contain dangerous methanol. Our clients sell our recovered product to customers with no problems.

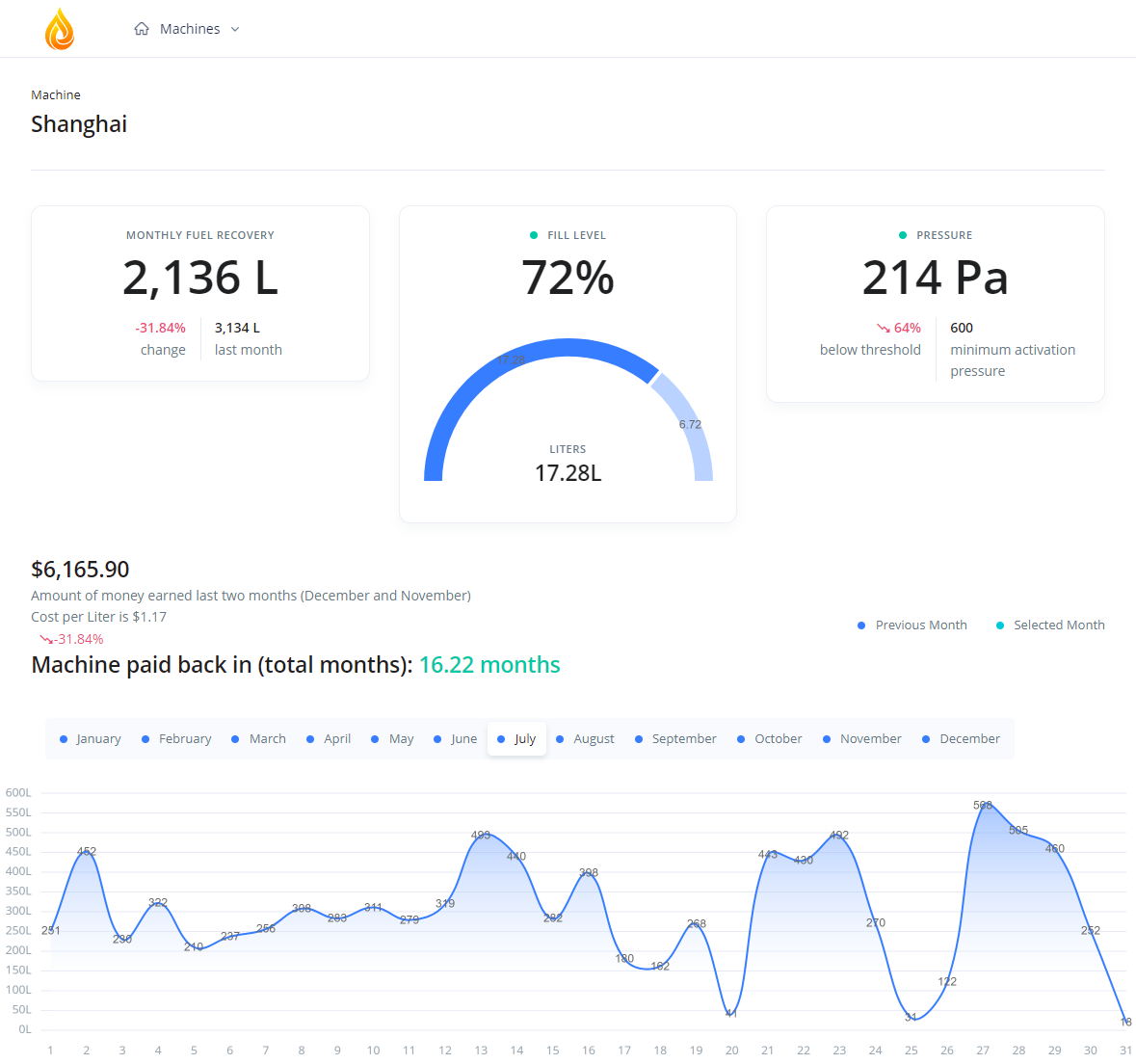

Analytics

We provide analytics via mobile or web app to see how much gasoline you have recovered and the equivalent amount of savings. We also provide analytics into the pressure, temperature, and other metrics to better give insight into the machine’s performance. In addition to the results measured by our PLCs, we verify the results using third party conformity testing.

Stakeholders who care more about the environment than profit will also be delighted by our analytics showing how many metric tons of carbon and the equivalent amount of trees planted in impact our machines have delivered for you so you can quantify how much your investment has helped the environment and the climate.